|

Our sincere thanks to Michael Conroy for allowing us to use some extracts and photographs from his book "Culm Crushers". Sections of this article relate directly to Michaels own memories as a young boy helping his father to "temper the culm" Bumbs were the poor man's coal or maybe they would be better described as the "smart man's (or woman's) coal. They could be made at no cost and of course like everything else, when their value was recognised they became a commercial commodity. Everybody wanted them, and they started to be mass produced. Their ingredients which originally were available free were then charged for. When our Teacher was young he remembers helping an old man, Joe Doyle, to make "Bumbs". Joe lived at the end of the street and used to take the local youngsters fishing. In return they often gathered yellow clay for Joe to make his "Bumbs" with. Half dry cow dung also did the trick but the young fellows were not too keen to collect that ingredient. Joe got culm (coal dust) free from the "Park" (the local mine). It was just regarded as waste that time and the owners were grateful to anybody who would take it away. |

|

|

|

|

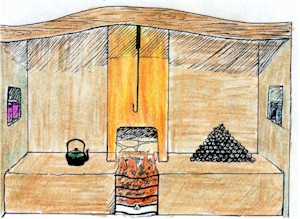

Open Fire burning "Coal Bumbs" and some turf "Briquettes" |

|

|

When coal is worked, there will always be a certain amount of dust or

fine material extracted with the coal. The particular name given to this

material depends on the type of coal that is being extracted. The fine

material from "bituminous" coal is generally known as

"slack", which was much

favoured by blacksmiths

for their smithy work, while the fine dusty or gritty material from the

anthracite coalfields was called " culm". The culm has been widely used for

hundreds of years in lreland to make culm balls (Bumbs) for burning in

domestic fires and for burning lime. Burning Culm The culm, or "duff", as it was sometimes called, was difficult if not impossible to burn in domestic fires unless it was first made into "culm" balls" by mixing the culm with yellow clay in certain proportions. The dried culm balls, or even the wet culm balls, were burned in an open grate fireplace in just the same way as anthracite coal. Many methods were used down through the years to mix or temper the culm and yellow clay, including simply mixing it with a shovel and walking on the culm and clay which was usually called "dancing the culm". Another method widely used was to trample the culm and clay in a large circle with a horse. In parts of Tipperary, a horse and cart were driven up and down the road on the culm and clay until it was sufficiently tempered. In parts of Carlow, Kilkenny and Laois, where horse- drawn churns were used up to the advent of the creameries, the culm and clay were tempered under the horse's feet at the same time as the farmers churned the cream into butter. One of the most sophisticated and technically superior ways of tempering the culm was to mix the culm and yellow clay until it was properly tempered under the "Culm Crusher", a large edge-runner grinding stone usually drawn by a horse or other draught animal. These culm crushers are found in the Castlecomer region only. I remember as a young lad going with my Father in the early fifties to the Stoney Orchard, outside the village of Leighlinbridge, to temper a few beds of culm. It was my job to fetch the odd bucket of water from the river Barrow nearby, and to lead the pony around on the circular path pulling the culm stone at a slow even pace. The heavy roller rotated in the well-worn groove on the flagstone grinding the culm until it was tempered. I would be glad to see the mixture of culm and yellow clay beginning to stick to the grinding stone, because we were now coming near the end of our morning's work. A little more water was added to the mixture and with a little more grinding my Father was satisfied that it was properly mixed. It was then loaded back on the car and taken home where it was shaped into culm balls by my Mother and burned in the open grate. The "balls" were always known as "bums" in our area. Uses |

|

|

|

|

|

The culm makes balls when mixed

with clay |

A mixture of culm and yellow clay was ground to a putty by the stone, and the bombs were made by hand or by a bomber and allowed to set. When they were set they burned well. |

|

|

|

|

Culm balls were burned throughout the Castlecomer and other

coalmining areas in Ireland for almost four centuries. this figure shows a

pyramid of bombs ready for burning in the small grate between the large

hobs of the open fireplace. |

|

|

|

|

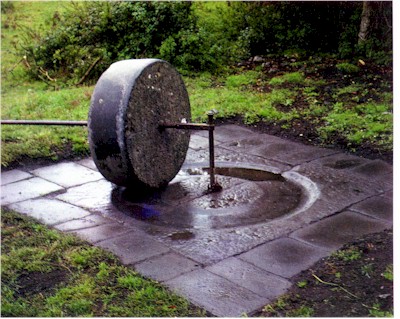

| Culm crusher where the culm was ground on the limestone base by the limestone grinding stone. Note the well-cut groove on the two limestone base stones. | |