Michael was not a miner, his early years at the Deerpark were spent as a carpenter but he later worked in the "Time Office" where he was responsible for recording the hours worked by the miners and most important ensuring that after a shift every miner came up safely from the pit.

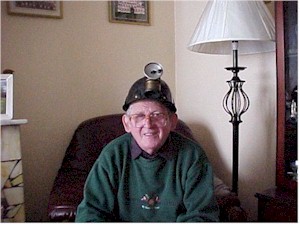

Michael Farrell

Interview with Mr. Michael Doogue

We asked Michael to give us a general description of the Deerpark Mine and the various works carried out there.

There

was a main road going

down the mine and various

roads leading from it. There

was about six or seven inches

of a gummy substance under

the coal. When the Miners had

that hacked out they bored holes into the coal and put in an explosive

called gelignite. Removing the “Gum” was called “Gumming” and

there was a special rate of pay for that work. When the gelignite went off

the coal fell into the place that they had cleared out. They broke the

coal with a four pound hammer and picks, then they brought it out to the

main road and put it into trams.

The

trams pulled the coal out to the surface and on to the “bank”. There would

be wooden props to hold up the roof where the coal came out. The props

would be about a foot and a half apart depending on what the roof was

like.

"Copleys"

was the last place worked in the Deerpark pit. It was shut in 1965 but

opened again later until 1969. When "Copleys" closed, men went to other

parts of the country to find work. The mine started up again on a

smaller scale and they went back to the old methods of coalmining. There

were only about 180 men left then and maybe only 100 men under ground. The areas worked were

Copleys, The Catbrook, Grants Flat and the Fault.

In the Fault you could work for about five to six months on the one seam

of coal and all of a sudden you could meet rock. It could be up to seven

feet thick. The miners would blast that out with gelignite and then just

worked on with the coal.

Coal

was brought from Copleys and the Catbrook to Grants Flat and

from there it was brought to the surface. Grants Flat was the main

part of the mine under ground. It was about 15 or 20 yards wide. It had to

be wide enough for two trams

to pass each other. Every man that worked in the mine had a little brass

medal and if they lost that they would have to buy a new one. If a worker

lost his tag he was to tell the time officer. They would make a new one in

the Forge. It was actually an identification tag. Every morning the

workers would have to collect their

identity tag before they went down the mine. They would have to give them

back to the time officer in the evening. The time officer could not leave

the office until every one of the workers was finished and the tags were

all back in place. If the medal was not there the time officer would have

to contact the fire man (the fore man). The time officer could not leave

the office until the word had come as to where the missing man was.

There

would be a shift in the night in which thirty or forty people were

involved. At one stage over seven hundred men worked in the mines. On

Saturday they would work a

four-hour shift. There would be a fortnight pay docket. There was money

taken off for gelignite, hospital bills, baths, carbide, candles, shovels

etc. An average worker would bring home £23.07 for a fortnights

work. There was an allowance made for digging out stones and poor quality

coal. There would be an allowance if the workers had to work in water or

if the roof had fallen in and they had to clear it. All the dirt would be

taken up to Bells Heap. Bells Heap was a heap of dirt and stones at the

edge of the mine.

If

you were making a road in the mines you would get so much a yard. Jobbing

men were people who did every sort of

work. The Miners had a

place for hanging their

shovels, picks and hammers etc. Wedges were used for splitting coal. The

hammers were used for breaking it.

In

the old days the Miner went to work, worked all day and returned home in

the same set of clothes. You can imagine how filthy and wet these clothes

were. The mothers dried out the clothes in the evening around the fire and

even by putting them up the chimney. Any hot water in these houses came

from boiling big pots of water on the “hob” (the open fire) Many homes

had nine or ten sons working at the pit so the work of the mother was

fairly hard. In the morning the miners would beat their clothes against

the gable end of the house to try to soften them. Around 1945 a great

improvement in the working conditions of the miners was made with the

building of the “baths”. The baths were modern hot showers with 1200

lockers. Each miner had two lockers –one for clean clothes and one for

dirty clothes. This development meant that the miner could come to work in

clean dry clothes, do his days work in working clothes and then return

home clean and in dry clothes. Of course the Miners had to pay about two

shillings a week for these luxurious showers, however they were quite

happy to do so.

Boys

commenced working at the pit at fourteen years of age. They

started off picking

stones and slates off the “belt”. After twelve months they had the

option of going down the pit. Before they went down the pit they had to

get a medical certificate of health.

When coal arrived at “bank” ie. came to the surface in trams, a clerk at the surface would weigh the coal. The trams were checked to make sure that the workers were not cheating. They were to make sure there were no stones in the tram. If a miner had stones in the tram he would not get paid for it.

English

coal “bituminous coal” had gas in it and burned with a flame.

Anthracite ('comer coal) had no gas. It reddened up when burning. Because

of this there was no hazard of exploding gas in the local mines and it

also meant that the miners could use “carbide lamps”

Mr

Doogue sometimes had to go down in the mine with the boss Mr Bambling to check measurements.

The

trams were hauled on a track by what was known as a “continuous rope”.

This steel rope pulled full trams to the surface, through the “billy”

where they were emptied and

then back down below to be filled again. As the trams were coming to bank

the rope often broke and as many as 20 full trams went hurtling back down

the mine. This was called a “play” and needless to say you would not

want to be travelling the “roads” when there was a play. It was

illegal to be on the roads when the haulage ropes were in motion. You

would loose your job if you were caught. Every so often along the

“roads” there were places to “step in” when the haulage commenced.

Sometimes the young miners would jump into the empty trams that were

travelling down the mines. This could save them a two mile difficult walk

to their place of work but it could also cost them dearly- their

“Life”.

The

coal was graded on the surface. There were two areas the

"Higher" landing and the

"Lower"

landing. The coal came out of the mine and the trams went down along the

Higher landing. They passed through the

“billy” which tipped them over and sent the coal along a

conveyer belt where stones

were picked out and then coal was graded into sizes by screens. The boxes came out of the pit two at a time. As

the coal passed through the screens to be “sized” it fell to the

“Lower landing” where train carriages and horse cars backed in to be

filled with coal for the market.

There

were six men working in the sawmill cutting timber for the props. There

were 5 Carpenters, 9 Electricians and

about 12 fitters working at Deer Park.

In

the later days there was electricity in the Deerpark mines. Only the main

roads in the mines had electricity. Before that the candle was used and

they were replaced by the Carbide lamp. Deerpark had its own generator. It

was fuelled by steam which was produced from a big coal furnace. They did however use ESB as well. The Deer Park was the

largest customer of the ESB. From November

to January there was a large demand on the ESB for electricity so

the Deerpark would use it’s own generator at this time so as to allow

the ESB to meet the requirements of it’s other customers.

“Shunting”

was another specialized job on the surface. The shunters work was to move

the train carriages in under the landing to be filled and then “shunt”

them back along a slight incline to the train. The shunting was done by

placing a wooden pole into the spokes of the carriage wheels and rotating

them with a lever action. This area was out of bounds to all but the

shunters as the moving carriages presented a very grave danger. At least

one person was killed at Deerpark in this area. He had come to collect a

ration of coal with his donkey and cart, strayed into the shunting area

and was hit by a full carriage of coal.

Deer Park Collieries Coal Processing

This process goes through what is called a "Jigger" screening operation , which means that there are various screens with different size holes which grades the coal to that particular size starting with cobbles (3”)to screen breakage (3/4”) (8 different grades from 3”to ¾”). This is then conveyed to the picking belt areas where each grade of coal has its own special conveyor.

It is here that the final operation of the cleaning of the coal takes place by the pickers. At this point we have the finished product ready for distribution. Each conveyor has its own special loading bay underneath for the loading of its particular grade to the customers (lorries etc.). Each conveyor can be moved up or down for loading purposes if so requested.